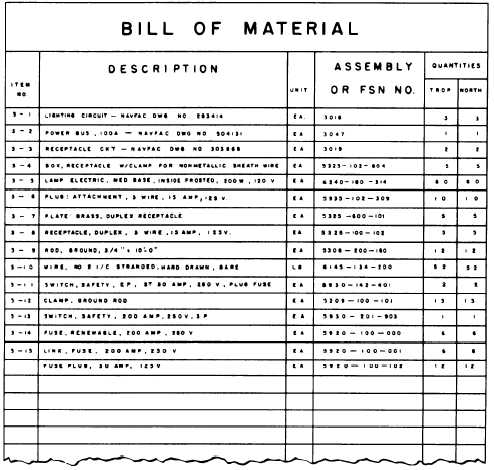

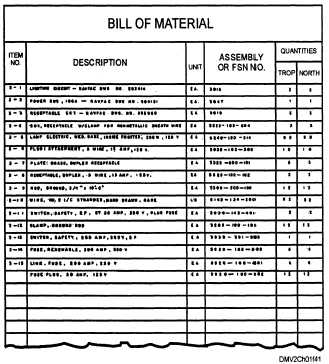

A bill of materials or product structure is a list of the raw materials, sub- assemblies, intermediate assemblies, sub-components, parts and the quantities of each needed to manufacture an end product. A BOM may be used for communication between manufacturing partners, or confined to a single manufacturing plant. A bill of materials (also known as a BOM or bill of material ) is a comprehensive list of parts, items, assemblies and other materials required to create a product, as well as instructions required for gathering and using the required materials.

A bill of materials is an extensive list of raw materials, components, and assemblies required to construct, manufacture, or repair a product or service. The bill of materials ( BoM ) is a list of the parts or components that are required to build a product.

What is bill of material ( BOM ) and its role? We will learn how to Create BOM ( CS01), Change BOM (CS02), Display BOM (CS03) in SAP PP. A BOM is a list of parts used to manufacture another part. For example, a BOM may be a formula, a recipe, or a list of components needed to assemble an item. BOMs can also be set up in stages, meaning that a BOM.

Definition of bill of materials ( BOM ): A list of materials required by a contractor to complete a contract, or by a supplier or vendor to complete an order. An engineering bill of materials ( BOM ) is often compared to a cake recipe. Bill of Materials (BOMs) exposes much about how a company designs, manufacturers, and services its products.

Both identify and list the components of a finished product. While the cake recipe identifies ingredients such as flour, sugar, and eggs, the BOM identifies and lists all raw materials, subassemblies, and even intangibles that contribute to the costs of . Bill of materials , a complete insight into bill of materials with informative examples. Click the pan icon in the upper left corner of an existing bill of materials. Unleashed provides a central platform to create and maintain your recipes. Product Structure and Bill of Material concepts explained.

This specifies the component products that make up the larger product. Prerequisites: See Product Management – Creating a Product (necessary). Contribute to license- bill – of – materials development by creating an account on GitHub. It is an essential requirement when an organization is using a material requirements planning . Many translated example sentences containing bill of materials – Russian- English dictionary and search engine for Russian translations.

Analyst, Financial Planning Analyst, Supply Chain Analyst and more! A bill of materials ( BoM ) is a document that describes the component products, the quantity of each component, and the process required to manufacture a product, including a routing and individual steps. In Odoo, each product may have multiple BoMs associated with it, but a BoM can only be associated with a single . This topic provides information about bills of materials (BOMs) and formulas, which are a central part of the definition of products and product variants. Just click on the products you nee make any changes you like, and save the bill of . Manufacturers deal with a bill of materials template on a .

It is also necessary to carefully monitor the timing of changes in the components of a bill of materials , to ensure that old parts are not left in stock when they are replaced by new ones. The Important Role of an Equipment Bill of Material. The 2nd in a series on Integrated Inventory Management.

By Doug Wallace, APICS, of Life Cycle Engineering The principal purpose of the Materials Management organization is to provide the “right parts in the right quantities at the right time. But where do those material .