EC – motors described in the article allow for energy consumption reduction while increasing the equipment performance and time-to-fail. Keywords: EC – motor ,EC- fan, energy saving equipment. When energy-efficiency costs come into play, more designers are opting for the electronically commutated motor rather than familiar AC and DC versions.

Although ebm-papst, the market leader in EC technology, is a German company, EC has nothing to do with the European Community! Basic DC motors rely on carbon brushes and a commutation .

All electric motors work by the interaction of two magnetic fields pushing on each other. One field is created by the rotor and one by the stator. The difference between motor types is in how these fields are created and controlled: EC motors use permanent magnets to create the rotor fiel and a series of coils controlled by an . The most common type of AC motor, the induction motor, has been around for over 1years, and is still the workhorse of many industries. They come in a variety of sizes and power levels and are widely available.

However their efficiency is limited due to their outdated design. The alternative, EC motors or .

EC motor technology (Electronic Commutation, also called Brushless DC – BLDC ) provides high efficiency, long life, and speed control options to motion system designers. Johnson Electric, an industry leader in brushless motor technology has customized EC motors for many applications in Automotive and Industrial . One thing at electric motors is clear: energy costs through the life cycle represent the highest part of the overall operating costs. If the operating costs can be reduce profitability can be increased and your production becomes more environmentally friendly.

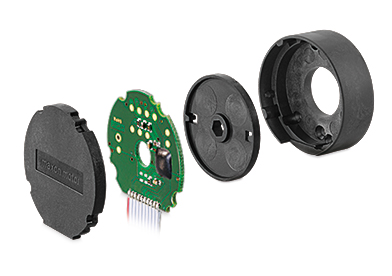

NS motors are electronically commutated ( EC ) motors available with or without integrated controller. Because of their optimized magnetic core, the brushless EC -i motors with iron core windings offer a very high torque density and low cogging torque. The multi- pole internal rotor is extremely dynamic.

Its solid design with a steel flange and housing make this motor suitable for a wide range of applications. The high-power 4-pole motors provide maximum performance per unit of volume and weight. In the HVAC market, the term “ EC motor ” is commonly understood to mean a specific type of motor, which many users associate with compact construction and high efficiency. EC motors are based on the idea of using electronic commutation (EC) instead of conventional carbon brush commutation for DC . Size, weight, longevity and efficiency have all contributed to their success. This article explores the benefits of these motors over the traditional PSC motor.

The benefits are clear and convincing: high energy efficiency, easy to install and ideal for new buildings and renovations. Read more on the following pages! ENERVEX is currently in the process of replacing all AC motors with Domel EC motors using a proprietary EDrive (VFD).

Why are we taking such a drastic step? The electronically commutated maxon EC motors stand out with excellent torque characteristics, high power, an extremely wide speed range, and an outstandingly long life span. The outstanding controllability of the motors makes high-precision positioning drives possible.

The economical EC series is called maxon . The two dots mark the pump size shown as an example in Fig. Designed for long uptime. The efficiency gain using EC motors increases for lower motor . EC -max drives takes the principle behind the A -max and RE-max programs one step further. The EC series is considered as one of the most complete and innovative technological control systems for optimising the function of EC fans (with single and three-phase motor ). This control unit allows the ventilation system to be adjusted to specific energy saving requirements, and boosts the potential of the EC fans. However in EC motors , the mechanical commutation and the brushes are replaced by an electrical commutation.

The major advantages are that they . Die offizielle Website von WOLF Anlagen-Technik: Klimatechnik, Oberflächentechnik, Landtechnik – Spirit of Air. The brushless EC flat motors offer an attractive combination of high performance and a low price. Providing energy efficient, custom EC motors , fans and controls for commercial refrigeration. Our EC motors feature an extremely high life -span, are robust and maintenance-free since – apart from the bearing system – they do not dispose of any mechanical wear parts.

The motors are highly efficient (up to a level of approx. ) and have an excellent power capability.