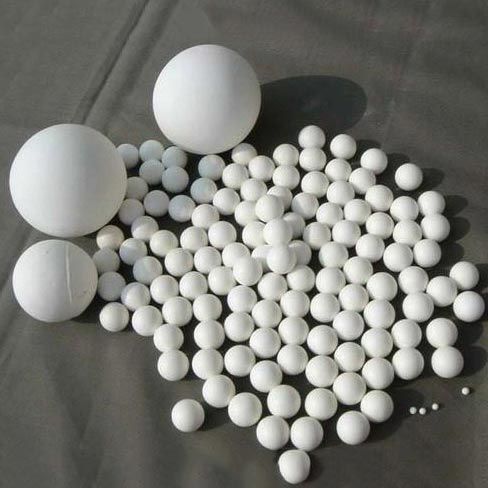

Ceramic balls are extremely har resistant to abrasion, and immune to all furnace atmospheres. CeramicSpeed use ceramic balls from a few manufacturers. The balls are made from Silicon Nitride and are of an especially high quality, creating balls with unique properties.

They are made from a variety of ceramic materials. LILY Bearing provide a wide range of ceramic ball options .

High quality ceramic precision balls supplier: ask for a quote with quantity, diameter and additional info you desire. Balls are the simplest, regular formed packing elements. Packing with balls has a comparatively small surface per packed volume. Because of the low void fraction of the packing, the pressure drop is quite high.

Bearing friction is less likely to increase as temperature increases when using ceramics and heat absorption is considerably less than other materials allowing lower cooling requirements. These qualities make ceramic balls useful for flow control, metering and bearing applications in harsh environments. Their main advantages on steel is that they have a density lower than steel, have lower thermal expansion and are 1 harder.

In certain high-speed applications their life is extended hundred times.

It is also used as grinding media. Ceramic precision balls are available in various materials and dimensions. Precision balls are applied in several products, such as valves, ball bearings or measuring equipment. Ceratec holds a large stock of precision balls , ready to supply. Toshiba Materials offers silicon nitride (Si3N4) fine ceramics that have high strength, high stiffness and high abrasion resistance for various structural parts.

In particular, they essential materials for high-performance bearings and are applied to many bearings in diversified fields. Many ceramic balls are capable of achieving an extremely smooth . CEMA offers GSi3NCeramic balls for use in loose ball wheel systems, . Ceramic Ball have many advantages compared to Steel Balls. Balls manufactured from ceramic materials are extremely resistant to corrosion and abrasion, and offer excellent performance characteristics. TRD Specialties offers a variety of precision ceramic balls , each providing its own unique corrosion and heat resistant qualities. Alumina Oxide Balls Alumina oxide.

After the ball is sintere the part lines are removed via finish- grinding. Lapping and precision finishing is then used to design or grade dimensions and product specifications such as diameter, sphericity, and surface finish. With the right material combination, customers can also see a significantly reduced thermal conductivity as well as the ability to hold up in extreme . Unasis provide a wide range of ceramic ball options across a variety of sizes.

Ceramic balls have excellent resistance to wear and seizure, they offer solutions for high temperature environments.

MetallBall is a French manufacturer of high precision steel balls and ceramic balls. We hold all the required production and inspection tools to satisfy the most critical requirements such as aerospace, space and medical. Find all the manufacturers of ceramic ball and contact them directly on DirectIndustry.

In general, ceramic products,in your case the balls , could be easily produced by sintering process. First, the ceramic powder with the incorporating additive – binders generally – is moulded and pressed at high pressure to produce the green product. Then the green product is heated to burn off the binders. The stiffness, light weight and inertness of silicon nitride offer significant bearing performance .