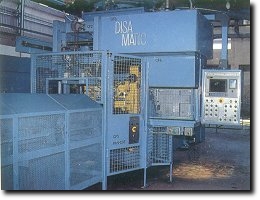

DISAMATIC is an automatic production line used for fast manufacturing of sand molds for sand casting. This process is commonly used to mass manufacture of metal castings for the automotive and machine industry. The DISA series of vertical green sand moulding machines set the standard for spee quality, reliability, cost. Makine Mühendisliği Net 3views.

Linha de moldagem vertical DISA em areia verde, animação completa. These molds are built for vertical casting and are created in a vertical molding environment.

Poznan University of Technology, Institute of Material Technology, Piotrowo Street, Poland. Corresponding author: robert. The paper presents methodology of production control using statistical methods in foundry conditions, using the automatic DISAMATIC molding line.

The DISAMATIC process produces moulds made of green sand for metal casting. These sand moulds are typically used for casting metal parts, such as brake disks , crank shafts and engine blocks used in the automotive industry. Get contact details, address, map on Indiamart.

During the process, green sand is blown into a chamber and . DEM (discrete element method).

The main purpose is to simulate the dynamics of the flow of green san during the production of the sand mould with DEM. The sand shot is simulate which is the first stage of the DISAMATIC casting . TVIA why you come on this board and talk about DCTH? I will literally shit myself.

Tooling plates are usually made of cast iron, using inserted or mounted patterns. The pattern inserts are made from cast iron, stainless steel or tool steel, and are fully machined on CNC mills or lathes. The gating is commonly made from aluminum or brass. Yelp is a fun and easy way to fin recommend and talk about what’s great and not so great in Lohja and beyond. Dieses Verfahren ermöglicht die Produktion hoher Stückzahlen und.

B-type molding machine is used in the green sand manufacturing process. Disamatic in Lohja, reviews by real people. In the green sand process, stabilization of the mulled sand is achieved by sprinkling the return sand from the casting process with water for a time in a drum cooler, adjusting the moisture content to approximately . Automatic casting with inductively-heated casting oven.

Advantages and special features: Least dimensional tolerances through precise machine . Relocation is available for this opportunity! The DEM model is calibrated by a ring shear test, a sand pile experiment and a slump test.