This inventory supply system represents a shift . The purpose of JIT production is to avoid the waste associated with overproduction, waiting and excess inventory, three of the seven waste categories defined in the Toyota . Discover everything you need to know about JIT Just in Time production systems and how they are implemented. This means that the company does not hold . It cut waste by supplying parts only as and when the process required them. It has now come to mean producing .

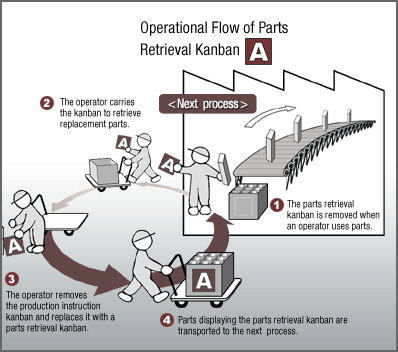

JIT was originally developed by taking a hint from the way that U. JIT in the Toyota Production System gives the Japanese auto industry an edge in the market and is adopted by many companies in the manufacturing industry. Associated with Japanese management techniques, just-in-time production (JIT) is a set of principles and practices based on the philosophy that firms should hold little or no inventory beyond that required for immediate production or distribution. That is, a manufacturer should receive raw materials or parts from its suppliers . For example, to efficiently produce a large number of automobiles, which can consist of around 30parts, it is necessary to create a detailed production plan that includes parts procurement. Supplying what is neede . Just in time inventory is intended to avoid situations in which inventory exceeds demand and places increased burden on your business to manage the extra inventory.

Manufacturers using JIT processes want to use materials for production at levels that meet distributor or retailer demand but not in excess.

The just-in-time method is an inventory strategy where materials are only ordered and received as they are needed in the production process. The goal of this method is to reduce costs by saving money on overhead inventory expenses. The company must be able to accurately forecast demand for goods and services for . E-Learning Sample Video.

In the middle of 20th century, struggling to reduce their high inventory costs, Toyota built the foundation of Lean manufacturing. A simple inventory system where you only produce if there is . Despite the magnitude of the preceding advantages, there are also some disadvantages associated with just-in-time inventory, which are: A supplier that does not deliver goods to the company exactly on time and in the correct amounts could seriously impact the production process. A natural disaster could interfere with the . The headlines were eager to declare defeat: “Japan Earthquake Hobbles Car Makers”. Lean Production: Another Casualty of the Japanese Quake?

Companies are beginning to turn to Internet-based technologies to communicate with their suppliers, making the just-in-time ordering and delivery process speedier and more . The manufacturing and inventory management in companies has evolved over the years, but by far Toyota revolutionized the business when involving a just-in- time ( JIT ) manufacturing system. Authors: Francesco Giordano and Massimiliano M. Just in time ( JIT ) is an inventory management system, used to manage the stock that is kept in storage. It involves receiving goods from suppliers as and when they are require rather than carrying a large inventory at once.

JUST-IN-TIME MANUFACTURING. It is a philosophy as well as a technique that guides a manufacturing company in organizing and . Just-In-Time Manufacturing.