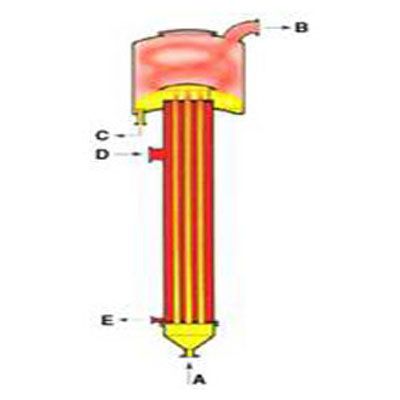

The liquid to be concentrated is supplied to the top of the heating tubes and distributed in such a way as to flow down the inside of the tube walls as a thin film. The liquid film starts to boil due to the external heating of the heating tubes and is partially evaporated as a result. The downward flow, caused initially by gravity,. A falling film evaporator is an industrial device to concentrate solutions, especially with heat sensitive components.

The evaporator is a special type of heat exchanger. Horizontal versus vertical.

Falling Film Evaporator Operation. Working principle of a falling film evaporator : a vertical shell-and-tube heat exchanger, with a laterally or. Description of a falling film evaporator.

Evaporation occurs inside vertical tubes through a film of liquid established using one of several liquid distribution devices, the selection of which depends on the wetting rate on the tubes. This is one of the most commonly used evaporator types due to simplicity of operation, dependability of performance, low temperature . The falling film evaporator has two main configurations, which includes the horizontal and the vertical tube,The horizontal tube is the most common design used in the desalination industry. The vertical tube falling film function describes are under. The liquid is introduced at the top part of the vertical tubes, where it form a .

The Swenson falling film long-tube vertical evaporator is preferred for heat-sensitive liquors. A film of liquor flows down the inside of a tube and is circulated to maintain the required flow. Because the circulating pumps on each effect maintain the wetted tube surfaces, these evaporators have . We have modified the conventional evaporation systems by modifying the evaporator design, developing efficient bleeding system from the evaporator bodies and . The BP Engineering falling film evaporator system is a modern device used to achieve the required degree of fluid concentration. The multistage evaporator ( juice evaporator ) with falling juice film is the most important device of the production cycle.

It is used to condense apple juices as well as soft (coloured) fruits juices. A heat exchanger with vertical tubes, where a fluid is partially evaporated while flowing as a thin film downward on the heated tube-wall. Shop below and contact sellers directly. Buy and sell, industrial and process equipment on LabX.

They operate mostly as once-through units with short residence time (a few seconds). However, partial recirculation of the liquid may be desirable for . Find all the manufacturers of falling film evaporator and contact them directly on DirectIndustry. The cost-effective falling film evaporator is the most commonly used type of film evaporator due to its wide operating range.