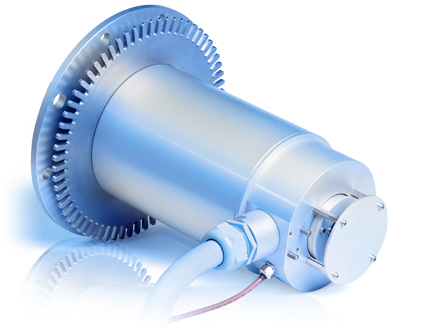

A slip ring is an electromechanical device that allows the transmission of power and electrical signals from a stationary to a rotating structure. A slip ring can be used in any electromechanical system that requires rotation while transmitting power or signals. It can improve mechanical performance, simplify system operation . Add wheel encoders, 3degree sensors, rotating LEDs, rotors and more!

Lean about how a slip ring transfers power and signal from a stationary member to a rotating member and vice.

The sliding contact is established by a brush that presses against a metal ring. The “brush” can look like a brush made from metal fibers, but more often it looks like a single wire or a spring with a pad of material affixed to the end that contacts the ring. Figure below shows a brush block for a four pass slip ring. MOFLON manufactures slip rings for more than years. SenRing is professional slip ring manufacturer with more than 18years experiences,owning RD center,factory and office both in China and USA.

Main products: through hole slip rings ,capsule slip rings ,Ethernet slip rings …and so on. Typical applications:CCTV monitor systems,Medical equipments,packing machines . Selection Matrix (images are for reference only).

Component-Kits Slip Rings – Woodhead Component-Kits Slip Rings. Electrical Slip Rings connection designed to pass the flow of current from a stationary device to a rotating component. UEA slip rings are versatile and can be customized for nearly any application. Thus, the applications range from current transmission at slowly moving circular scrapers in.

Slip ring manufacturer – Made in Germany. A component of an electromechanical device which, in combination with brushes, provides a continuous electrical connection between stationary and rotating conductors . Overview of the slip ring product groups offered by LTN Servotechnik GmbH. Conductix-Wampfler offers a wide range of slip rings and rotary joints for energy, data and signal transmission as well as for the transmission of gases and liquids.

BGB can manufacture custom units that combine power slip rings with signal, optical, hydraulic rotary joints. In this video, you’ll learn how to stitch a slip ring. Learn to crochet with an easy tutorial. Watch it for free today to take your crochet skills to a new level. A slip – ring assembly is often a solid metal and graphite or precious-metal wire brush, which contacts the outside diameter of a rotating metal ring.

As the ring turns, electrical . These pots are favorites of sports and commercial crabbers alike why not have a Crab Pot that you can trust and know that it is the best available. All Original Slip Rings include a Free Orange .

They mount rings with a special alloy on a steel shaft FIXED PART. Forks for brushes (sliding contacts) MOVING PART which, pushing on the rings through special steel springs ensure continuity of the electric contact. Rotary Systems has a variety of standard slip ring unions for a complete media transfer system. We also have custom design solutions for applications requiring more than our . Manufactured by Stemmann Technik. Rugged construction ideally suited for smaller oceanographic and ROV winches.

Easily modified to include two-pass fiber optic rotary joints. For the hazardous area environment, the FO180-X is a fully certified flameproof enclosure. When underwater operational . Our flagship line – R-Series – set the standard for quality in industrial slip ring design.

They are rugge built for long life, and easy to maintain. With an assortment of ring sizes, insulators, and bore sizes, we can assemble a ring that is ideally suited for the application. Changing brushes is easy. Each brush can be rotated out .