All-in-One Desktop Circuit Printer , Paste Dispenser and Pick and Place. The Top Desktop PCB Printers – SnapEDA Blog blog. Deadlines are an unpleasant part of life for an electronic designer. While design of a printed circuit board ( PCB ) can be done internally, manufacturing is generally outsourced.

This dependence often in uncontrollable, and unexpected delays.

Just imagine if you had to wait days or weeks to get an . Using permanent marker, a 3D printer and etching to create a PCB. I used FreePCB to create PCB layout and. Find great deals on eBay for PCB Printer in Manufacturing and Metalwork PCB Assembly Equipment. As we said later we wanted to build the printer without tier down or or re-use other ink printers or CNC machines. For this reason we designed everything from scratch.

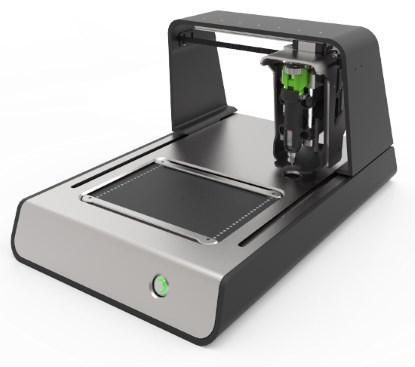

We thought that our PCB printer had to be low-cost, easy to build and printable with a 3D printer. We wanted to use an Arduino ONE for the electronics , .

Print your circuit boards, dispense solder. Voltera V-One Desktop PCB Printer. The magic happens in the middle.

Recently one of my focuses has been to find a way to make the PCB (Printed Circuit Board ) creation. Edgy startups and powerhouse corporations alike have to deal with the messy process of creating circuit boards for electronics. An Israeli start-up is now shipping to beta customers a 3D printer that can produce multi-layer circuit board prototypes, drastically cutting development time and ensuring that intellectual property remains in-house.

We combine expertise in multi-layer inkjet printing , nanoparticle inks, and software to make 3D printed electronics a reality. Say HELLO to rapid PCB prototyping. Take control of your PCB development today by joining our early access program.

STEP 1: Take a printout of circuit board layout. Keep in mind the following points: You should take the mirror print out. D circuit board printing : Sales and service.

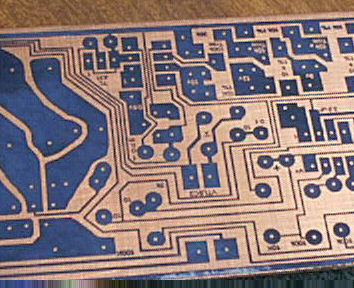

Phytec is ready to bring 3D printing of high resolution multilayer PCBs to your production. The Lunaris is an Etch Resist Printer , intended to operate in the manufacturing of printed circuit boards (PCBs). In current PCB production processes, the substrate is laminated with a photo resist and using a lithographic process the desired photo mask is created on the substrate.

With the development of the Lunaris, it is.

There are three methods to print the legend. Silk screen printing epoxy ink was the established method. It’s equipped with a Blu-Ray optical pickup (PHR-803T) and various UV laser components, and it uses dry . Squink, featured on Makezine. BW Printer image the entire BROTHER printer line does not work with our PCB process.

They use a non-standard toner formulation that does not work well with our process. Please refer to the listing at the bottom of this site page for the most up to date . That plane has been put through an ordinary printer , filled with an extraordinary ink made from silver nanoparticles. Normally, a circuit board made using the substance would need to be sintered in an oven at around 150C for a few hours for the minuscule metal particles to bond. This Pin was discovered by Mario Afonso.

Discover (and save!) your own Pins on Pinterest. Many engineers I know all want to fabricate PCBs for the custom, prototype, or one of a kind projects, but they often can not afford to have them printed at the volume many board houses require. What are some cheap PCB printing services out there? Personally, I am looking for board houses that will print 1 .