Advanced Circuits, as a regular part of its manufacturing process, performs electrical testing on your printed circuit boards to ensure their quality. Below please find a full explanation of how we perform these tests and what they mean. As a leading PCB manufacturer we assure you that we monitor for quality here in our own . We can perform a visual inspection following the manufacturing process of a printed circuit board to find any potential problems.

While that may work fine for a two-layer PCB , for multi-layer PCBs, it is almost impossible to visually inspect the internal layers once the board has been completed. Functional test (FCT) is used as a final manufacturing step.

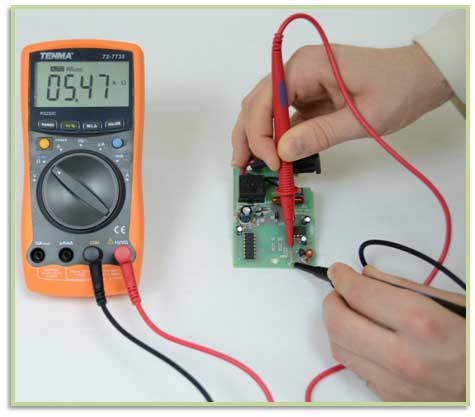

Why PCB Tests are required. Any electronic product even if properly designed and built with utmost care is prone to bug and issues. It is very crucial to test the product or PCB thoroughly in early stages of design to save millions of dollars later. The testing can be done at PCB design level wherein after . In-circuit test (ICT) is an example of white box testing where an electrical probe tests a populated printed circuit board ( PCB ), checking for shorts, opens, resistance, capacitance, and other basic quantities which will show whether the assembly was correctly fabricated.

It may be performed with a bed of nails type test fixture . This is video of a printed circuit board being electrically tested on a flying probe. This is an example of a PCB automated programming and functional test. NTS performs a Printed Circuit Board Testing.

Contact us today to learn more! Here is a general outline of how I would go about testing a PCB such as the one you described. PCB electrical testing at Omni Circuit Boards manufacturing facility. Helping you decide the most effective solution when embarking on a PCB assembly test strategy with your contract electronics manufacturing partner. Modern generation in-circuit testers include other test technologies as part of testers, like boundary scan tests, MDA functions etc.

With the increase in high- density PCBs and reduced real estate for test point and access, the ability to acquire interconnections between the tester and PCB has been progressively reduced. We provide PCB AOI testing service in canada and USA. Miniaturization of PCB components and increasing complexity of circuit boards is driving the need for Automated Optical Inspection testing.

We develop and manufacture In Circuit and Function Test Fixtures and Software for testing electronics boards and devices. We work with test engineers and production managers who need to outsource . In order for a PCB to function properly, each component must play its part: the result should be a PCB consisting of an array of conductive pathways, . C- test -mate is a handheld test system for functional testing of assembled PCBs without the need for complex tooling. Simply integrate eC- test -mate footprints into your PCB -layout, write your test programs, place the eC- test -mate test head(s) on your board and run the tests.

No connectors, no test jigs, just easy footprints. Once you have made the decision to test , EPA recommends that you first test the air to determine if building occupants may be exposed to PCBs in the indoor air. If you have identified a PCB problem, you will need to . The PCB manufacturing process includes a final electrical test to verify net continuity and the absence of shorts on the board.

In some markets, the increased complexity and variety of PCBs, along with decreasing volumes, have determined an extensive use of flying probe type test systems for electrical test.