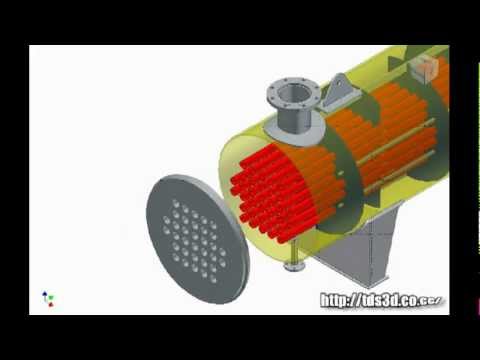

A shell and tube heat exchanger is a class of heat exchanger designs. It is the most common type of heat exchanger in oil refineries and other large chemical processes, and is suited for higher-pressure applications. As its name implies, this type of heat exchanger consists of a shell (a large pressure vessel) with a bundle of . Figure illustrates a typical unit that may be found in a petrochemical plant. Two fluids can exchange heat , one fluid flows over the outside of the tubes while the second fluid flows through the tubes.

Shell-and-tube heat exchanger.

Our shell and tube heat exchangers are used in many comfort and industry applications for heating and cooling fluids. They consist of a shell with traditional plain tubes or enhanced surface tubes for high thermal performance. Two fluids, of different starting temperatures, flow through the heat exchanger. One flows through the tubes (the tube side) and the other flows outside the tubes but inside the shell (the shell side).

Heat is transferred from one fluid to the other through the tube walls, either from tube side to shell side or vice versa. Selection of heat exchanger TEMA layout and number of passes. Specification of tube parameters – size, layout, pitch and material.

Setting upper and lower design limits on tube length.

In this model, two separated fluids at different temperatures flow through the heat exchanger, one through the tubes (tube side) and the other through the shell around the tubes (shell side). Several design parameters . A cylindrical shell with multiple tubes running inside the shell. There are many different types of heat exchangers currently available, and the shell and tube heat exchanger is one of those options. The flow path of the fluid within the . It is most commonly used in large chemical processes, including in oil refineries, but is certainly not limited to such industries.

Due to the fact that it is particularly well suited . Typically used in applications when a process requires large amounts of fluid to be heated or cooled. As a result of their design, shell tube heat exchangers offer a large surface area and thus high heat transfer efficiency. Sublime is a water-based solvent enhanced with wetting agents, corrosion inhibitors and degreasing compounds.

PROCESS DESIGN OF SHELL AND TUBE HEAT EXCHANGER , CONDENSER AND. Classification of heat exchangers. Thermal design considerations. The shell side usually contains the process fluid and the tube.

We provide a variety of applications based on the most suitabel materials. The internal hoses are welded in two perforated bases, which are then welded to the . Quality and safety – be it standard products or customised solutions. Standard model series andcustomer- oriented solutions .

In this paper, the new approach of constructal theory has been employed to design shell and tube heat exchangers. Constructal theory is a new method for optimal design in engineering applications. The purpose of this paper is optimization of shell and tube heat exchangers by reduction of total cost of the exchanger using .